Making production data usable for OEE efficiency

In times of growing variant diversity, increasing quality requirements and limited expert resources, traditional analysis methods are reaching their limits. An AI-supported analysis of production data helps companies to detect patterns and indications of causes.

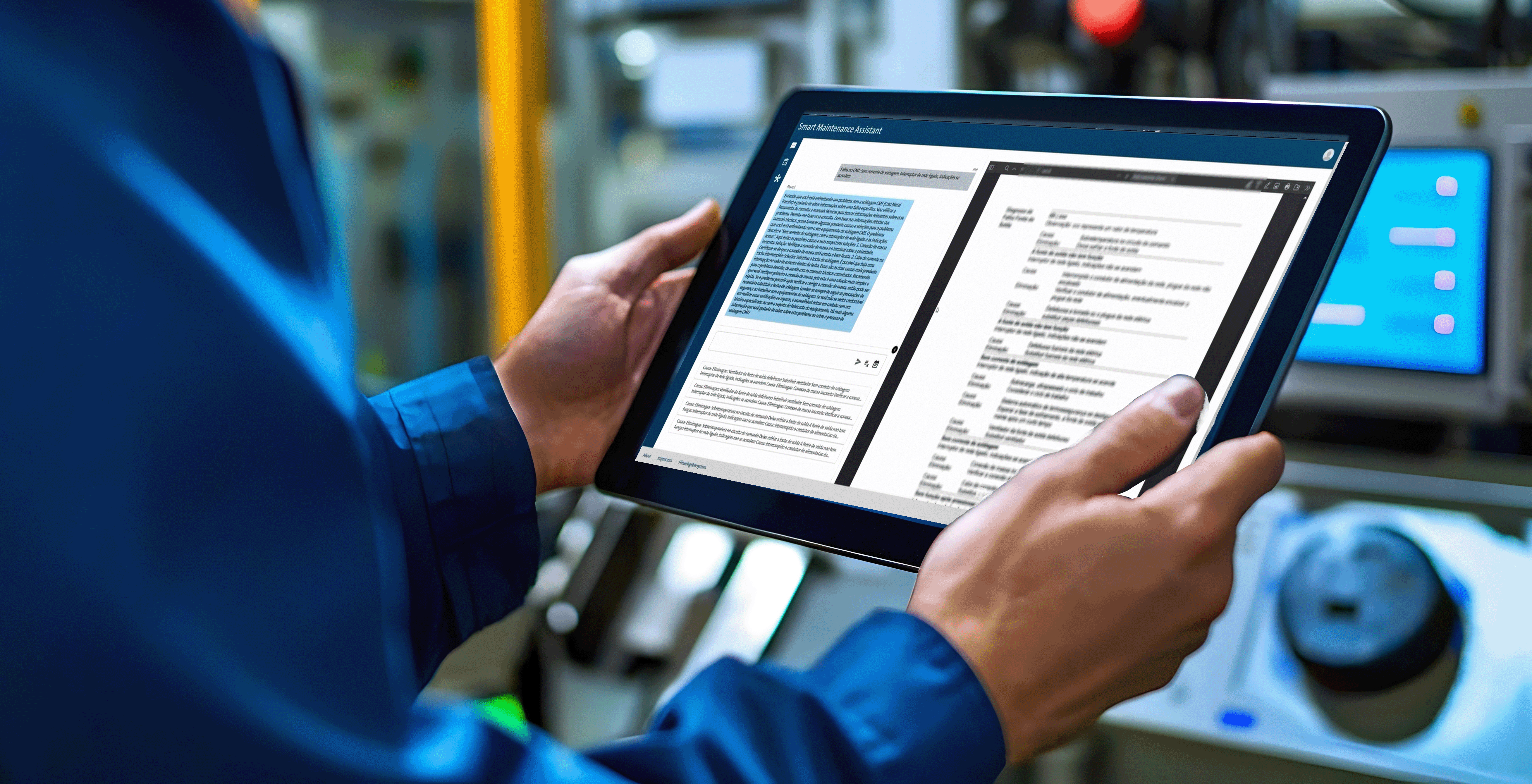

Live in Action: No Code AI

Focus: Increasing overall system effectiveness

Avoidance of errors

in ramp-up and inline production

Cost savings

due to lower

external maintenance costs

Higher product quality

inproinproinproinpr nproinpr

More efficient production processes

Expansion of AI expertise in production

Strengthening the continuous improvement process

AI development: AI-supported analysis of production data

The challenge

The goal of every plant or production manager is smooth production and high product quality. If errors or machine downtimes occur more frequently, it is crucial to identify the causes quickly in order to avoid rework and downtime costs. As experienced specialists are not always available and the increasing complexity of products and processes presents a challenge even for experienced specialists, automated analyses based on existing data are becoming increasingly important. It is important to first understand the data and to quickly and easily check its suitability for machine learning. As data scientists are rare and expensive, solutions are needed that also work without in-depth expert knowledge.

The implementation

The AI-powered analysis of production data based on the Mendix development platform was specifically designed for professionals in manufacturing – not for data scientists. The AI application supports users directly in the continuous improvement process, whether in the production unit, manufacturing cell, or office, and helps them systematically improve product quality and the runtime of production units. Users can import time-dependent production data, describe and condense it. Using a generated feature ranking, they can identify which factors are important, supporting them in deriving targeted improvement measures.

The result

The no-code solution creates the basis for the professional and automated continuous use of machine learning models in production, which can significantly reduce rework and downtime costs. The application can also be used in brownfield environments without the involvement of data scientists.

FAQs

Typical users of the No-Code AI Suite are project and process engineers with a basic understanding of artificial intelligence. IT and data managers can also provide support without AI knowledge if required.

Relevant input data can be, for example, process, sensor, movement, material flow or vehicle data. This data must be available in tabular form.

The result model generated by machine learning can be exported and made available for further use. Particular attention was paid to the integration capability in the Siemens Edge Solution environment.

Industrial AI solutions and use cases

Find out how you can use manuals and technical documentation effectively with AI chatbots and benefit directly from generative AI in production.

Find out how you can scale your AI solutions along the value chain with standardized AI hardware and software components.

Use our free checklist, derived from process frameworks such as CRISP-DM (CRoss Industry Standard Process for Data Mining) and TDSP (Team Data Science Process) to evaluate your AI use cases.

inpro

inpro