Industry of the future: AI solutions for greenfield and brownfield

Digital transformation of your entire value chain

Industry champions and our shared project successes

What our customers & partners say

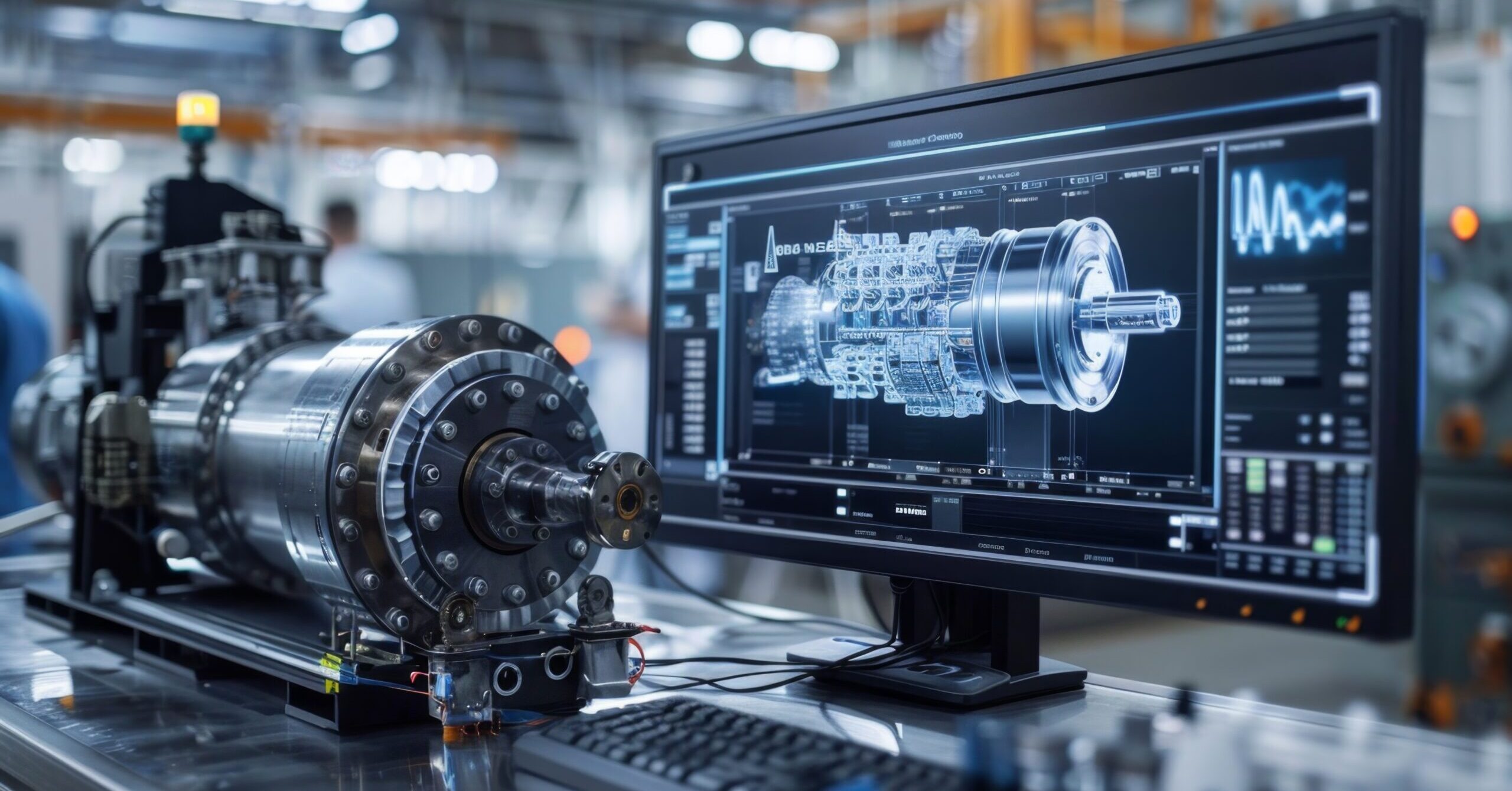

“End customers don’t ask for individual components – they seek solutions to their specific challenges. inpro delivers tailored solutions that directly address these needs.”

inpro

inpro