End-to-end simulation of process chains in automotive manufacturing.

At inpro, we have been involved in process and component simulation in automotive production since the 1980s, and have contributed to an ever-increasing level of digitalization in production planning for automotive suppliers and OEMs with numerous solutions and industry partnerships such as AutoForm and ESI Group.

Read in this blog post:

- What level of maturity simulation technologies have reached.

- What challenges need to be solved for end-to-end process chains

- Which potentials are realized by combining simulation methods with other technology approaches

- Which future trends will continue to occupy us in simulation

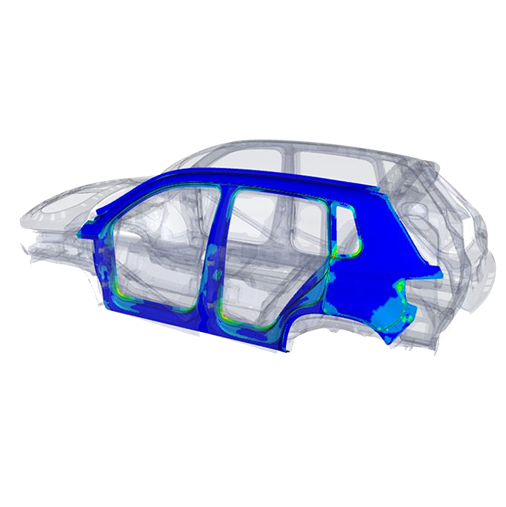

From research & development to industrial simulation solutions

Whether it is folding simulation to safeguard assembly processes for sheet metal components, simulation-supported avoidance of interference effects in one of the most important joining technologies, thermal welding, or optimization of the painting process for automobile bodies: Specific simulation tools are now routinely used in almost all areas of product development and production preparation in order to avoid costly problems in the real production start-up as far as possible. However, the development of such simulation solutions requires in-depth knowledge in the areas of modeling, physics, mathematics and computer science. New materials or new manufacturing technologies therefore often entail considerable R&D expenditure for industrially usable simulation solutions. Thanks to our decades of experience in the development of specific simulation tools and our unique approach to innovation through collaborative incubation, where we work together with industry partners on new industrial solutions, we can significantly accelerate this process.

simano: The toolbox for end-to-end process chains and data optimization in real time

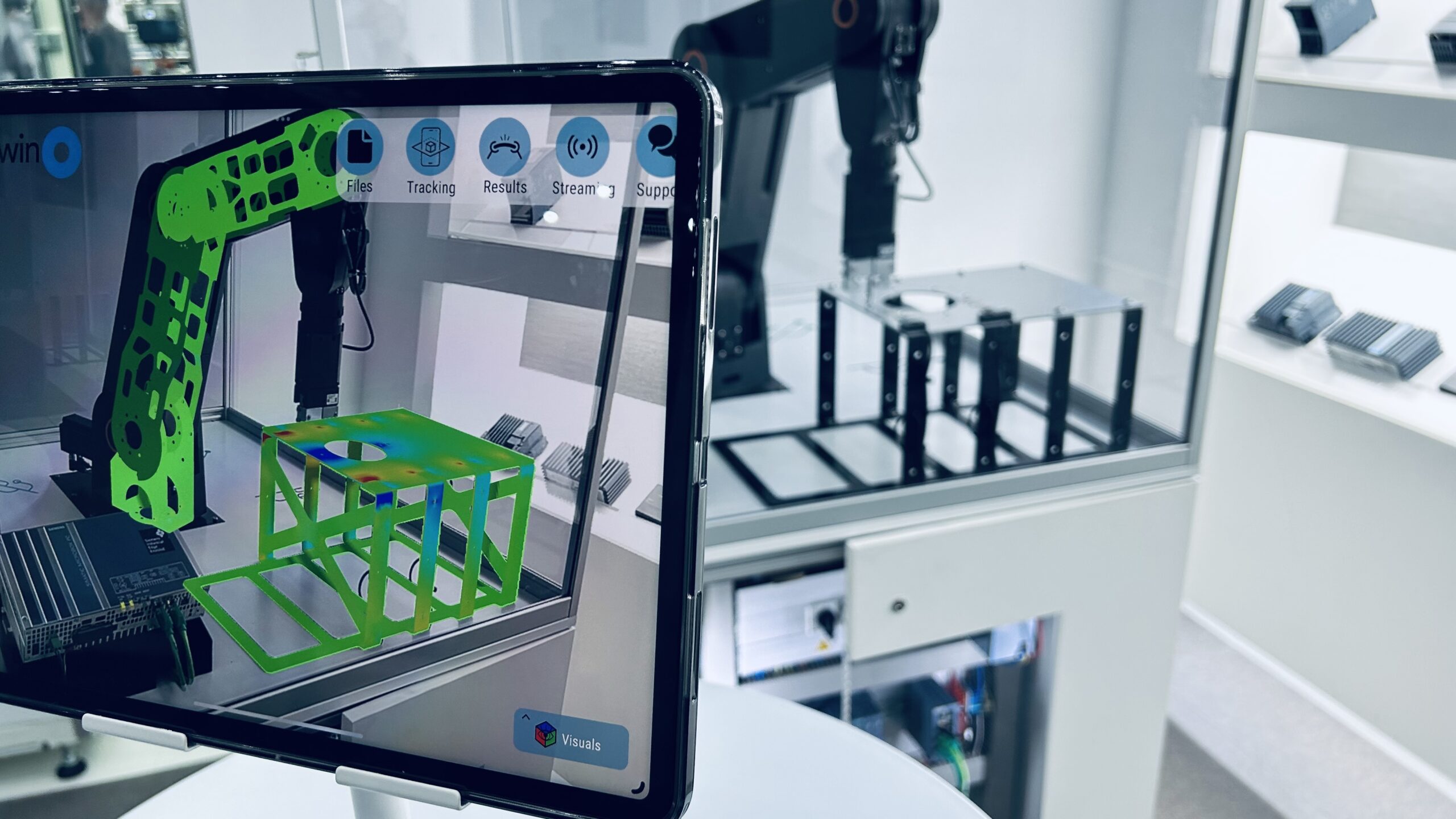

twino: The solution for simulation data management in real time

The future of body shop: sustainability targets and e-mobility

The automotive industry has always excelled in progressiveness. Due to the focus on sustainability and e-mobility, body manufacturing will continue to transform in the coming decade, which will also place great demands on simulation software providers. Although simulation methods can be applied in a new context, entirely new problems must be solved in order to actually realize today’s visions of modern automotive manufacturing, such as those of the digital factory. The reduction or even complete elimination of costly laboratory tests is the goal. Suitable simulation solutions must be continuously developed and adapted for new materials, designs and process flows.

Simulation as a success factor for the automotive industry 4.0

Simulation can reduce costs, shorten the time-to-market of new models and achieve sustainability goals. inpro is ready to actively shape the next generation of simulation technologies with its modular toolbox simano in combination with new technology approaches – as it has already done with augmented reality and the simulation application twino.

Contact us for a free live demo and discussion of your use cases.

Read more

Digital innovations in the injection molding industry

Injection molding has become a cornerstone of modern manufacturing, driven by continuous advancements in machine technology, material innovations—including multi-material molding—sensor integration, CAD/CAM systems, digital twins, and predictive maintenance solutions.

Industrial Metaverse: Technology, use cases and partnerships

Read this blog post to learn how the Industrial Metaverse can help you plan, model and implement production processes faster and more accurately.

inpro

inpro